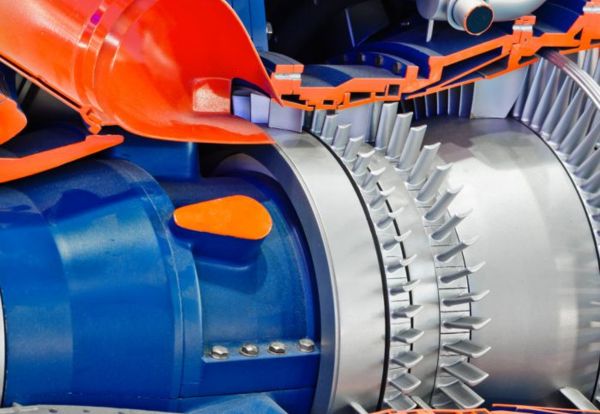

Raising the Bar in Gas Turbine Pressure Testing

Pressure scanners in a gas turbine environment play a crucial role in monitoring the complex interactions between air flow, aerothermal and thermodynamic characteristics, fuel flow, and mechanical components. Their ability to provide accurate, high-speed data in harsh conditions is particularly valued, helping ensure efficient operation, early detection of problems, and overall system safety.

The class leading Scanivalve DSA5000 pressure scanner, commonly used in gas turbine applications, is designed to meet the demanding requirements of engineers by providing precise, reliable, and fast pressure measurements in high-temperature, high-speed environments like gas turbines.

Here’s how the DSA5000 addresses the specific needs in this context:

High-Temperature Tolerance

Gas turbines operate at extremely high temperatures, particularly in areas like the combustion chamber and turbine stages. The DSA5000 series is built to withstand high temperatures, often featuring robust materials and thermal management systems that allow it to operate in these challenging environments without sacrificing accuracy or longevity.

Accuracy and Precision

Engineers require highly accurate data to ensure the optimal performance of gas turbines, as even minor discrepancies in pressure can lead to inefficiencies or system failures. The DSA5000 offers high-accuracy measurements, typically in the range of ±0.04%. This high precision ensures that engineers can trust the pressure data for optimizing performance and diagnosing issues.

High-Speed Data Acquisition

Gas turbines experience rapid changes in pressure, especially during transients like startup, shutdown, or load changes, necessitating fast data collection. The DSA5000 provides fast data acquisition rates, often up to 5,000Hz (Samples/Channel/Second) allowing engineers to capture high-speed dynamic events in the turbine environment. This capability is essential for monitoring real-time performance and detecting rapid fluctuations.

Multi-Channel Capability

Monitoring pressures at multiple locations across different stages of the gas turbine, including the compressor, combustion chamber, and turbine sections, builds a comprehensive pressure profile. The DSA5000 series typically supports multiple channel configurations (e.g., from 16 to over 1,500 channels), enabling fully simultaneous monitoring of pressures from various points in the turbine. This multi-channel capability is crucial for analysing the overall system performance and identifying localized issues.

Durability and Reliability

Gas turbines often operate continuously in critical applications like power generation or aviation, meaning pressure scanners must be durable and capable of functioning reliably over long periods without frequent maintenance. Built for durability, the DSA5000 is designed to operate in harsh environments, and handle continuous operation without frequent recalibration or failure. This reliability reduces downtime and maintenance costs, which is critical for turbine operations.

Compact and Lightweight Design

Gas turbine environments often have limited space, and pressure scanners must fit within tight confines without interfering with the turbine’s operation. The compact form of the DSA5000 makes it suitable for installation in the confined spaces typically found around turbine components. This allows engineers to place the scanner close to the measurement points, minimizing frequency response losses, signal degradation and installation complexity.

Dynamic Pressure Measurement

Engineers require both static and dynamic pressure data to analyse steady-state and transient phenomena in turbines, such as surges, oscillations, or other instabilities. With an excellent dynamic response, the DSA5000 allows engineers to capture both steady and fast-changing pressures from 4″H2O to 1,500psi pressure ranges. This feature is particularly useful for detecting critical events like compressor stalls, pressure pulsations, and vibrations that can affect turbine performance and safety.

Data Integration and Communication

Pressure data needs to be easily integrated into broader turbine monitoring systems, often requiring compatibility with existing data acquisition and control systems. The DSA5000 can be equipped with various communication interfaces (e.g., Ethernet and iDDS) that make it easy to integrate into turbine control systems or remote monitoring setups. This capability allows engineers to monitor and analyse data in real-time or send it to cloud-based systems for further analysis.

Calibration and Self-Diagnostics

Regular calibration is necessary for maintaining accuracy, and engineers need systems that can provide diagnostics to ensure proper functioning. As the DSA5000 offers automatic calibration routines and built-in self-diagnostics, it helps engineers quickly verify the system’s performance and reduce the need for manual intervention. This improves operational efficiency by ensuring accurate readings with minimal downtime.

Resistance to Harsh Environments

Gas turbine environments can expose sensors to high levels of vibration, chemical contaminants, and extreme conditions. The DSA5000 is designed to be resistant to these harsh conditions, with rugged housing and components that are able to handle the high vibration and possible exposure to chemicals or particulates (built in purge vales support this). This ensures long-term operational integrity and reliable performance in demanding environments.

The DSA5000 meets the needs of engineers in gas turbine applications by providing high-precision, high-speed, multi-channel pressure measurements in a durable and compact package. Its ability to operate in extreme temperatures, handle dynamic pressure fluctuations, and offer easy integration into turbine monitoring systems makes it an ideal solution for ensuring optimal performance and safety in gas turbine environments.

About Evolution Measurement:

Evolution Measurement is a UK-based company specialising in precision physical measurement, instrumentation, and calibration. Renowned for their expertise, they cater to industries that demand the highest standards of accuracy and reliability. Partnering with some of the world’s leading measurement instrumentation manufacturers, Evolution Measurement ensures its customers receive solutions that embody quality, efficiency, and precision.

Their reach extends beyond the UK, representing globally respected brands such as DMA, Guildline Instruments, Scanivalve, streamwise, and wekomm. Evolution Measurement is also recognised for its ability to deliver tailored solutions, excelling in multi-point pressure and temperature measurement. Central to their innovation is the EvoScann® range of miniature pressure scanners, a testament to their commitment to groundbreaking engineering and functionality.

www.evolutionmeasurement.com